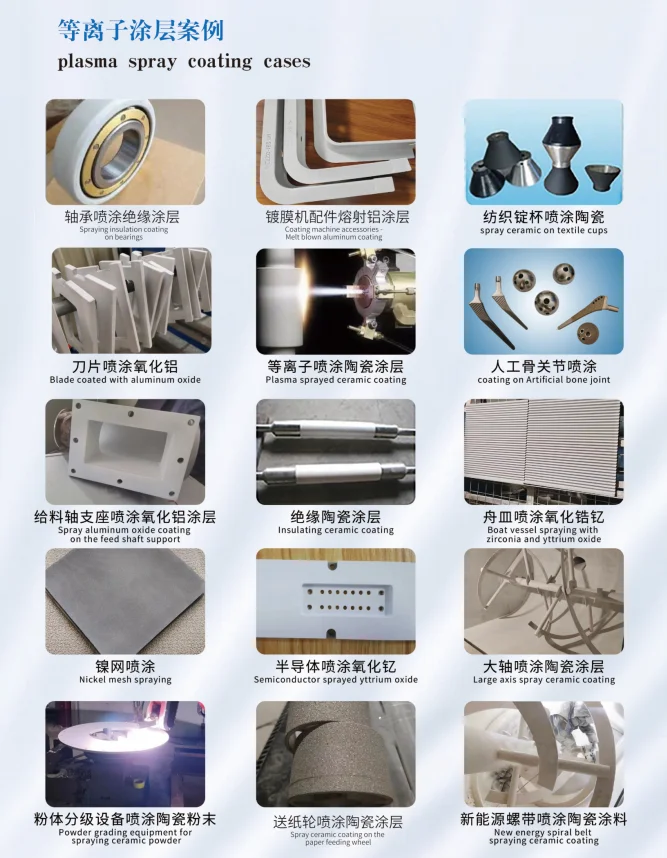

Plasma Coating Machine thermal spray coating machine with white aluminum oxide insulation coating

SX plasma series is designed for top quality thermal spray coating solution, not only metal and alloy coating, but also ceramic coating.

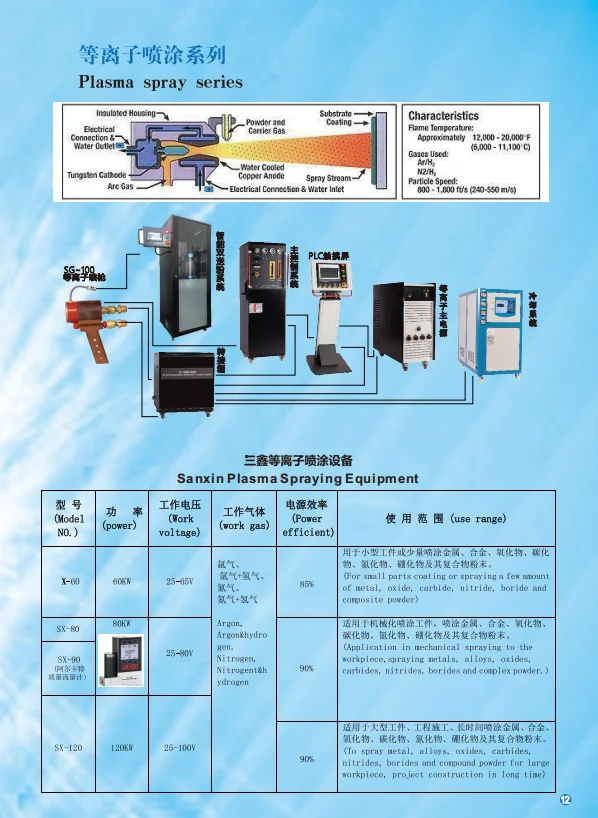

Model. SX-50 plasma spraying system utilizes Argon / Hydrogen / Nitrogen as working gas. Its comparatively low power will be suitable for applying metal, iron, nickel & cobalt based alloys, ceramic, carbides, cements, oxide and other composite powder on small components or small area with minimum energy consumption. It makes up the disadvantage of other alternative thermal spray technologies that can not apply ceramic material. PS-plasma spraying series are the best solution for needs of both metallic and ceramic high quality spray coating in one system.

Model. SX-80 is popular system in medical industry because its application of spraying titanium nitride coating. Smart Thermal Spray Plasma's system is designed for top quality thermal spray coating solution. PS-80 plasma spraying system utilizes Argon / Hydrogen / Nitrogen as working gas. Besides of titanium alloy, it can also apply iron, nickel & cobalt based alloys, ceramic, carbides, cements, oxide and other composite powder on workpieces and component. It makes up the disadvantage of other alternative thermal spray technologies that can not apply ceramic material. PS-plasma spraying series are the best solution for needs of both metallic and ceramic high quality spray coating in one system.

Model. SX-90 Adopting mass flow meter.

Model. SX-120 is suitable for special industrial coatings like thermal barrier coating, implant titanium and hydroxyapatite coatings. Also it is suitable for applying metal, iron, nickel & cobalt based alloys, ceramic, carbides, cements, oxide and other composite powder. PS-120 plasma spraying system utilizes Argon / Hydrogen / Nitrogen as working gas. Its comparatively high power allows it to apply on bigger workpieces, large component and bigger area for long time of non-stop working. The PS – plasma spraying series make up the disadvantage of other alternative thermal spray technologies that can not apply ceramic material. It’s the best solution for needs of both metallic and ceramic high quality spray coating in one system.